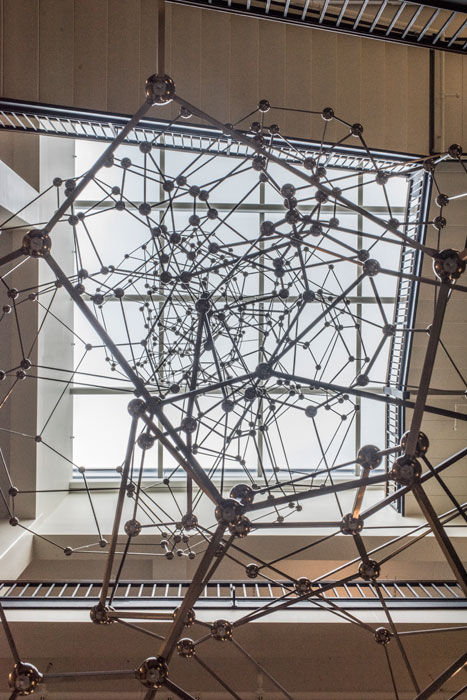

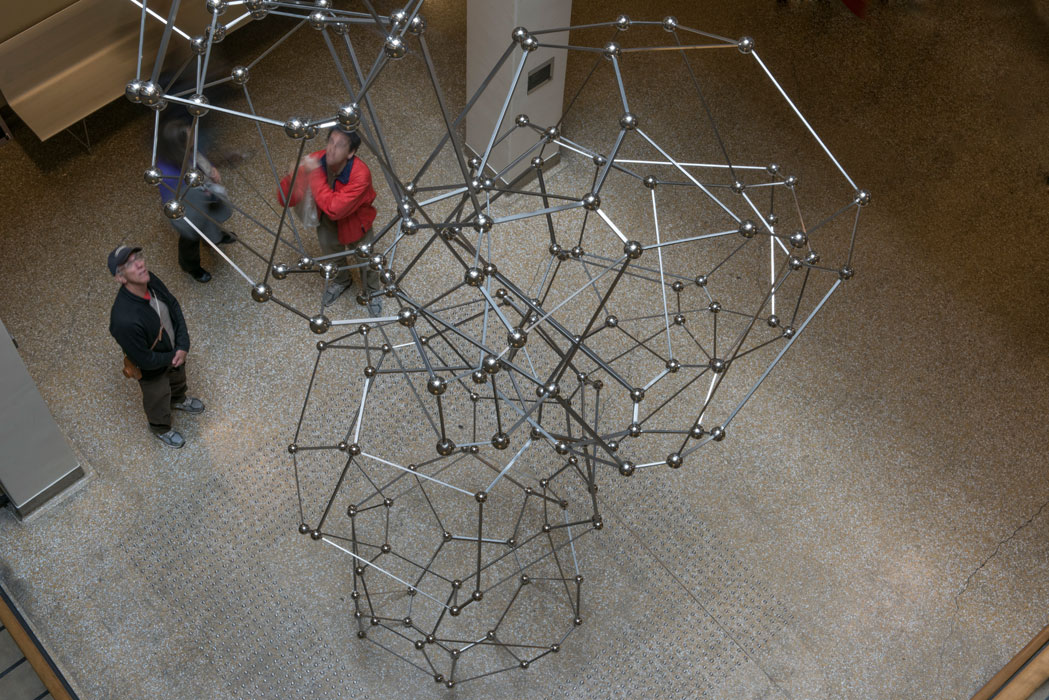

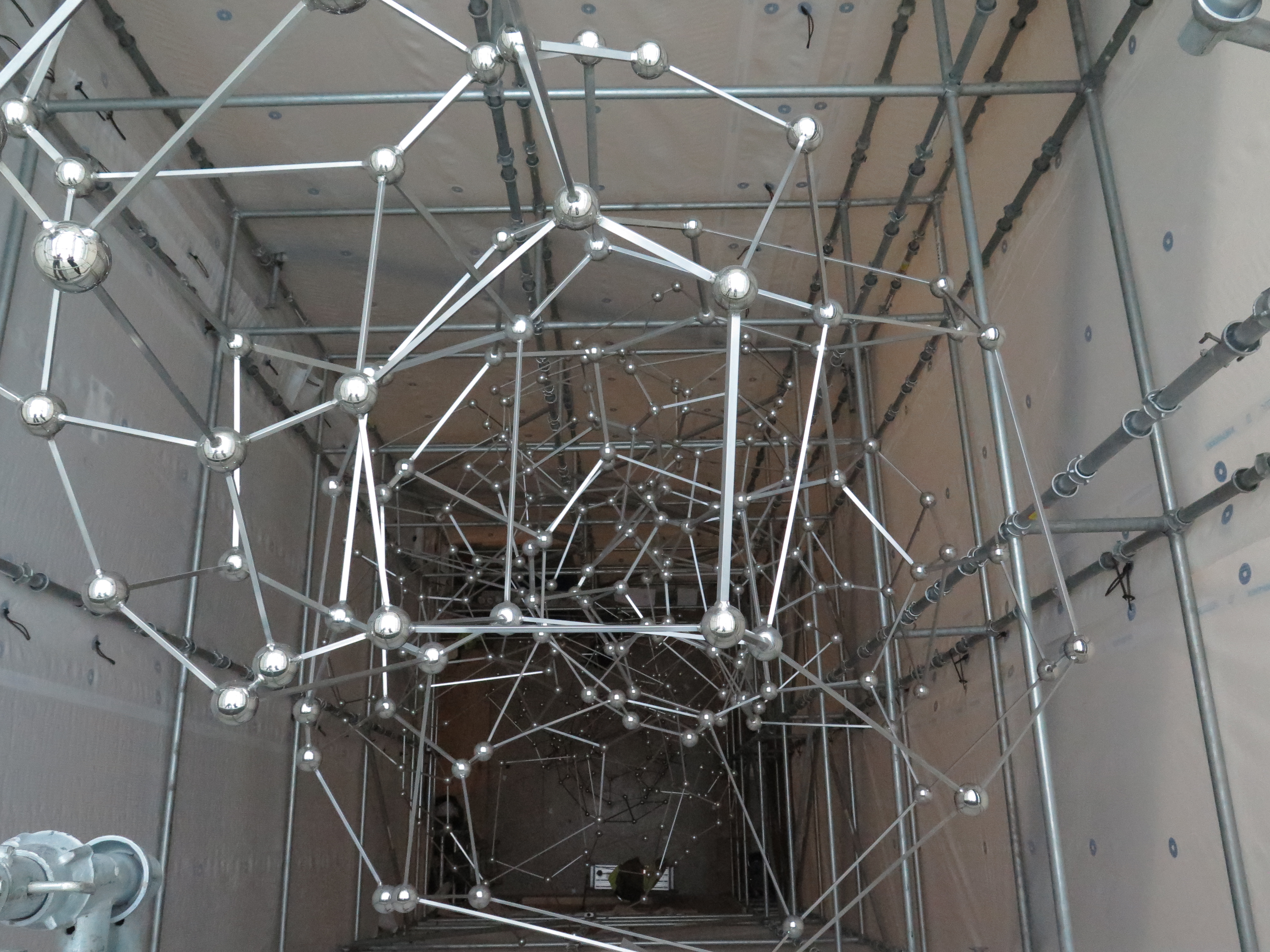

The sculpture was made in response to the stairwell and the light shaft at its core. It is attached to the building but has to have integrity and be virtually self-supporting. This consideration was an important contributor to CHORD's final form. It is suspended from the skylight and supported from the floor, connecting at the mid-point where the largest polyhedron lies.

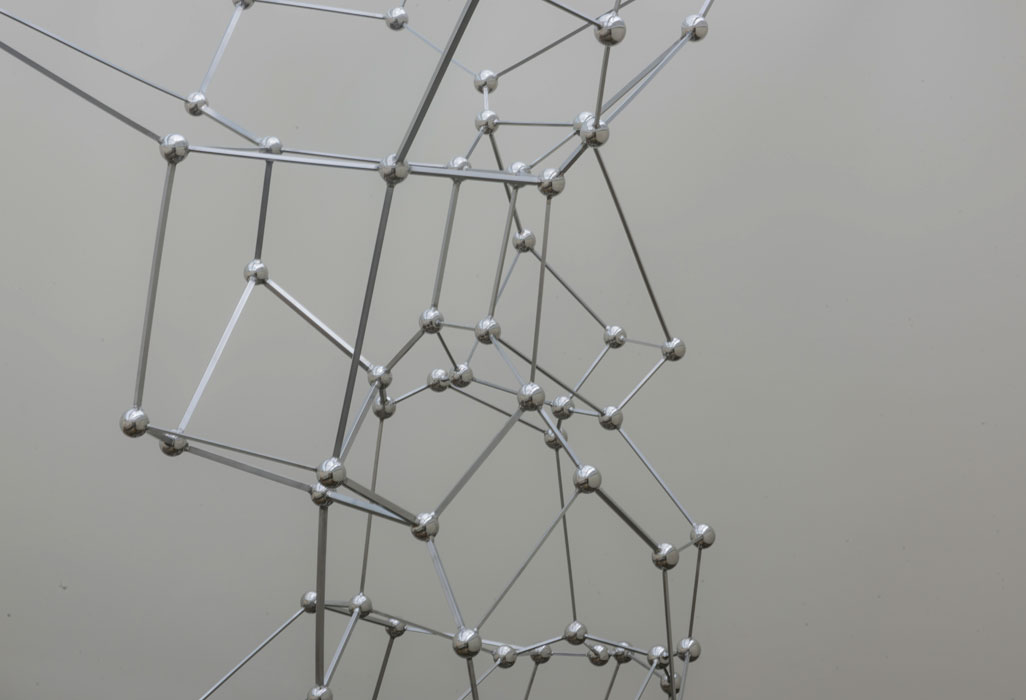

CHORD is a light-weight reply to the fixity of a column, an obelisk, or even Brancusi's 'Endless Column': all of these convey an impression of stability and make a solid bridge between above and below, whereas CHORD evokes a more dynamic relationship between matter and energy. This column is made of a myriad of polyhedra linked as a chain and they cluster in places of high tension. The balls reflect the world around them. This ball and element construct is used to model molecular structure but here is used without illustrating any particular molecule and eliminates all symmetry.

When making this work, what intrigued me was the reconciliation of the organic and the geometric. This geometry is a characteristic of foam structures, a universal and economic way to structure space: bubble geometries exist in the pith of desert grasses and in our bones. Its random yet principled matrices have been assumed into parametric design.

CHORD suggests connection (not least in the umbilical cord) but is also the harmonic of three notes. CHORD also suggests striking a chord and has the possibility of doing so with ascending and descending mathematicians. I hope it engages the body as well as the mind and is as elusive as it is definite: an open work calling upon a wide range of association while acknowledging the underlying geometry in all phenomena.

CHORD, 2016

CHORD, 2015, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

Overall size: 1706 x 321 x 341 cm

Permanent installation, MIT, Cambridge, Massachusetts, USA, 2016

Photograph by Peter Vanderwarker

CHORD, 2015, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

Overall size: 1706 x 321 x 341 cm

Permanent installation, MIT, Cambridge, Massachusetts, USA, 2016

Photograph by Peter Vanderwarker

CHORD, 2015, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

Overall size: 1706 x 321 x 341 cm

Permanent installation, MIT, Cambridge, Massachusetts, USA, 2016

Photograph by Peter Vanderwarker

CHORD, 2015, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

Overall size: 1706 x 321 x 341 cm

Permanent installation, MIT, Cambridge, Massachusetts, USA, 2016

Photograph by Peter Vanderwarker

CHORD, 2015, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

Overall size: 1706 x 321 x 341 cm

Permanent installation, MIT, Cambridge, Massachusetts, USA, 2016

Photograph by Peter Vanderwarker

CHORD, 2015, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

Overall size: 1706 x 321 x 341 cm

Permanent installation, MIT, Cambridge, Massachusetts, USA, 2016

Photograph by Peter Vanderwarker

CHORD, 2015, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

Overall size: 1706 x 321 x 341 cm

Permanent installation, MIT, Cambridge, Massachusetts, USA, 2016

Photograph by Peter Vanderwarker

CHORD, 2015, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

Overall size: 1706 x 321 x 341 cm

Permanent installation, MIT, Cambridge, Massachusetts, USA, 2016

Photograph by Peter Vanderwarker

CHORD, 2015, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

Overall size: 1706 x 321 x 341 cm

Permanent installation, MIT, Cambridge, Massachusetts, USA, 2016

Photograph by Peter Vanderwarker

CHORD, 2015, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

Overall size: 1706 x 321 x 341 cm

Permanent installation, MIT, Cambridge, Massachusetts, USA, 2016

Photograph by Peter Vanderwarker

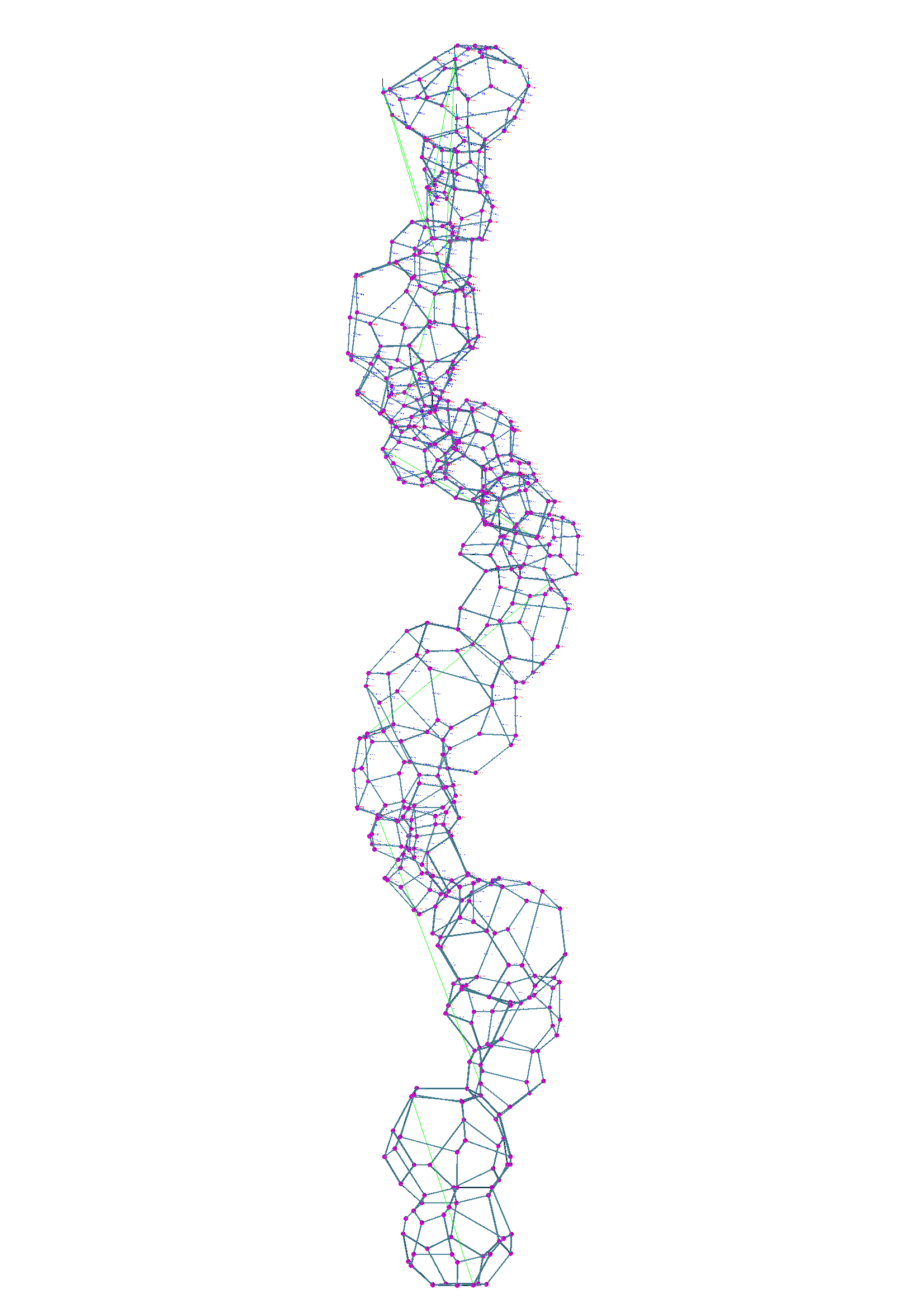

WORK IN PROGRESS

CHORD, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

1706 x 321 x 341 cm

Digital render

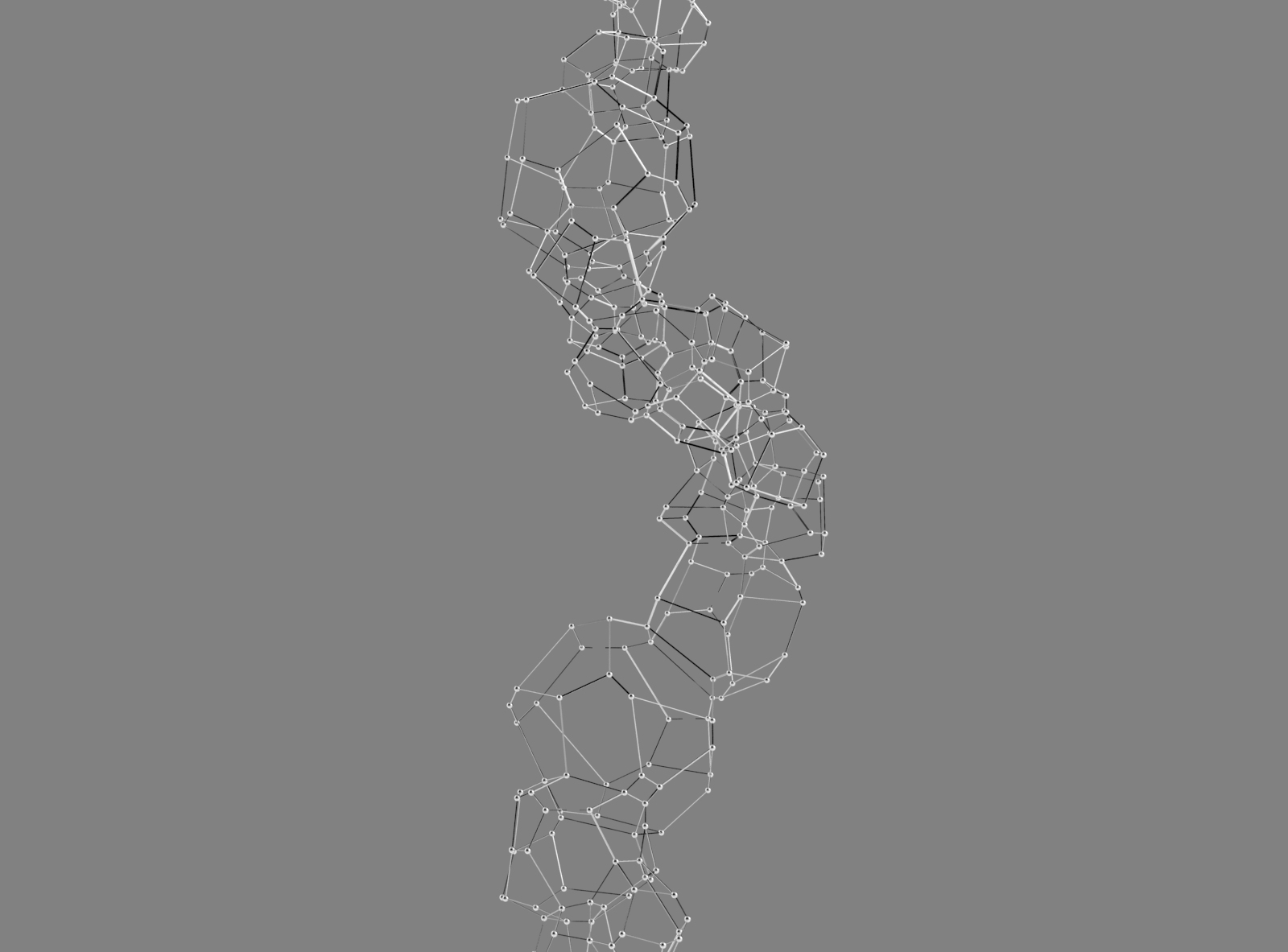

WORK IN PROGRESS

CHORD, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

1706 x 321 x 341 cm

Digital render

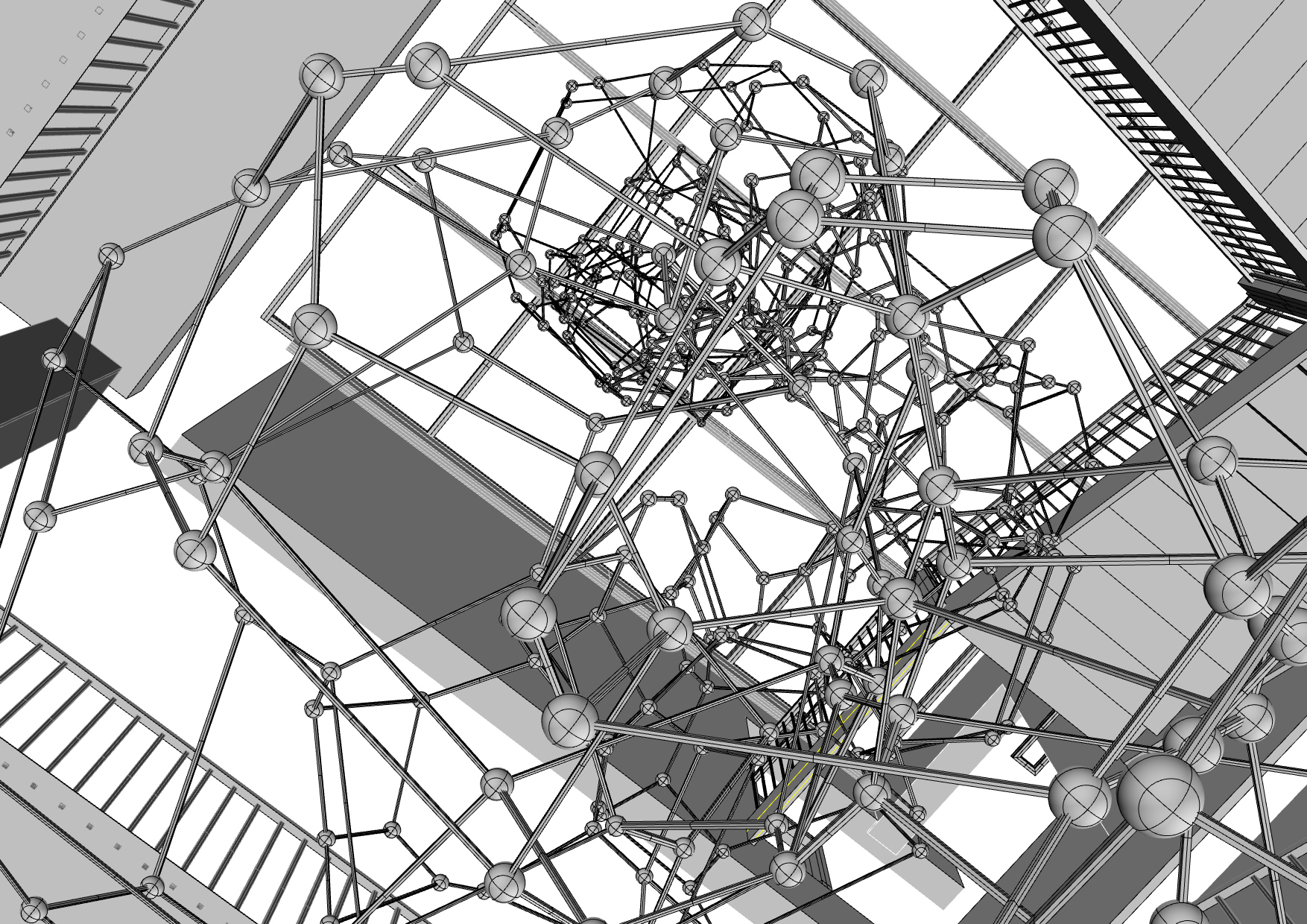

WORK IN PROGRESS

CHORD, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

1706 x 321 x 341 cm

Digital render

WORK IN PROGRESS

CHORD, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

1706 x 321 x 341 cm

Fabrication, Summit Metal Fabricators, New Hampshire, USA

WORK IN PROGRESS

CHORD, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

1706 x 321 x 341 cm

Fabrication, Summit Metal Fabricators, New Hampshire, USA

WORK IN PROGRESS

CHORD, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

1706 x 321 x 341 cm

Fabrication, Summit Metal Fabricators, New Hampshire, USA

WORK IN PROGRESS

CHORD, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

1706 x 321 x 341 cm

Fabrication, Summit Metal Fabricators, New Hampshire, USA

WORK IN PROGRESS

CHORD, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

1706 x 321 x 341 cm

Work in Progress

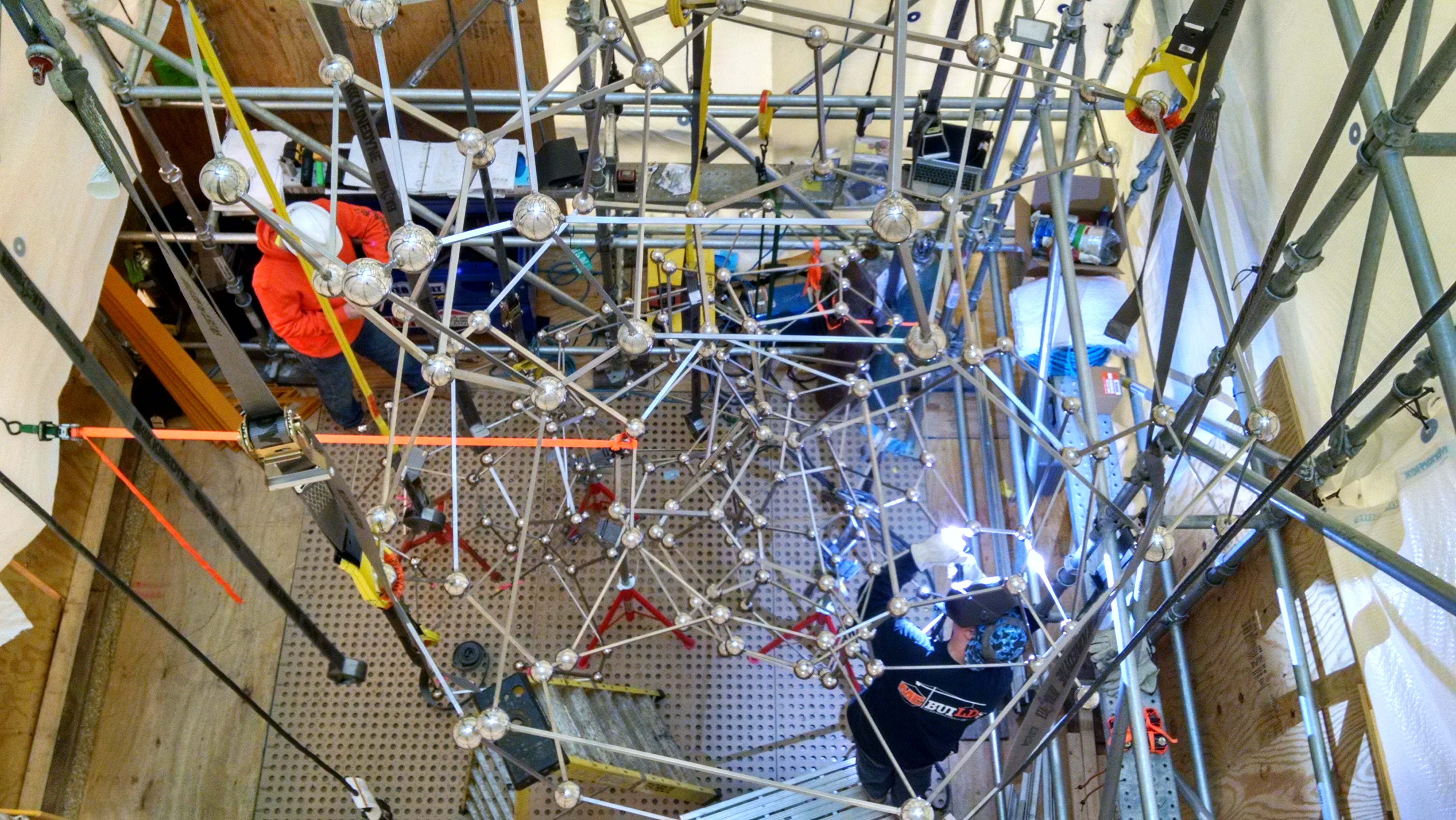

WORK IN PROGRESS

CHORD, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

1706 x 321 x 341 cm

Installing, MIT Cambridge

WORK IN PROGRESS

CHORD, 2016

Variable square section stainless steel bar and 60 mm stainless steel balls

1706 x 321 x 341 cm

Installing, MIT Cambridge